- #Stock inventory manager how to#

- #Stock inventory manager manual#

- #Stock inventory manager software#

This provides better customer service and strong brand recognition.īut good inventory management is also important to the long-term financial health of a business. Customers can get what they want when they want it without having to seek alternate sources. That balance allows companies to fulfill orders and drives customer satisfaction. With the right balance of materials, cash is only expended for what is needed, and even then, it is expended as close as possible to the point of invoice. Good inventory management strikes a balance in that “thin” middle ground to help a company reduce costs. And while this is a drain on any manufacturer or distributor, it can be especially destructive to the cash flow and overall, health of SMBs.

#Stock inventory manager manual#

The reason for this back and forth between “too much” and “not enough” highlights the dangers of manual inventory management but also highlights the importance of good, dependable, accurate, and real-time inventory management. For while stock-outs and overages account for the extremes, there is little middle ground, and companies can find themselves veering from one extreme to another. But here lies one of the failings of “old-school” inventory management that relies on spreadsheets, paper counting, and manual inputs.

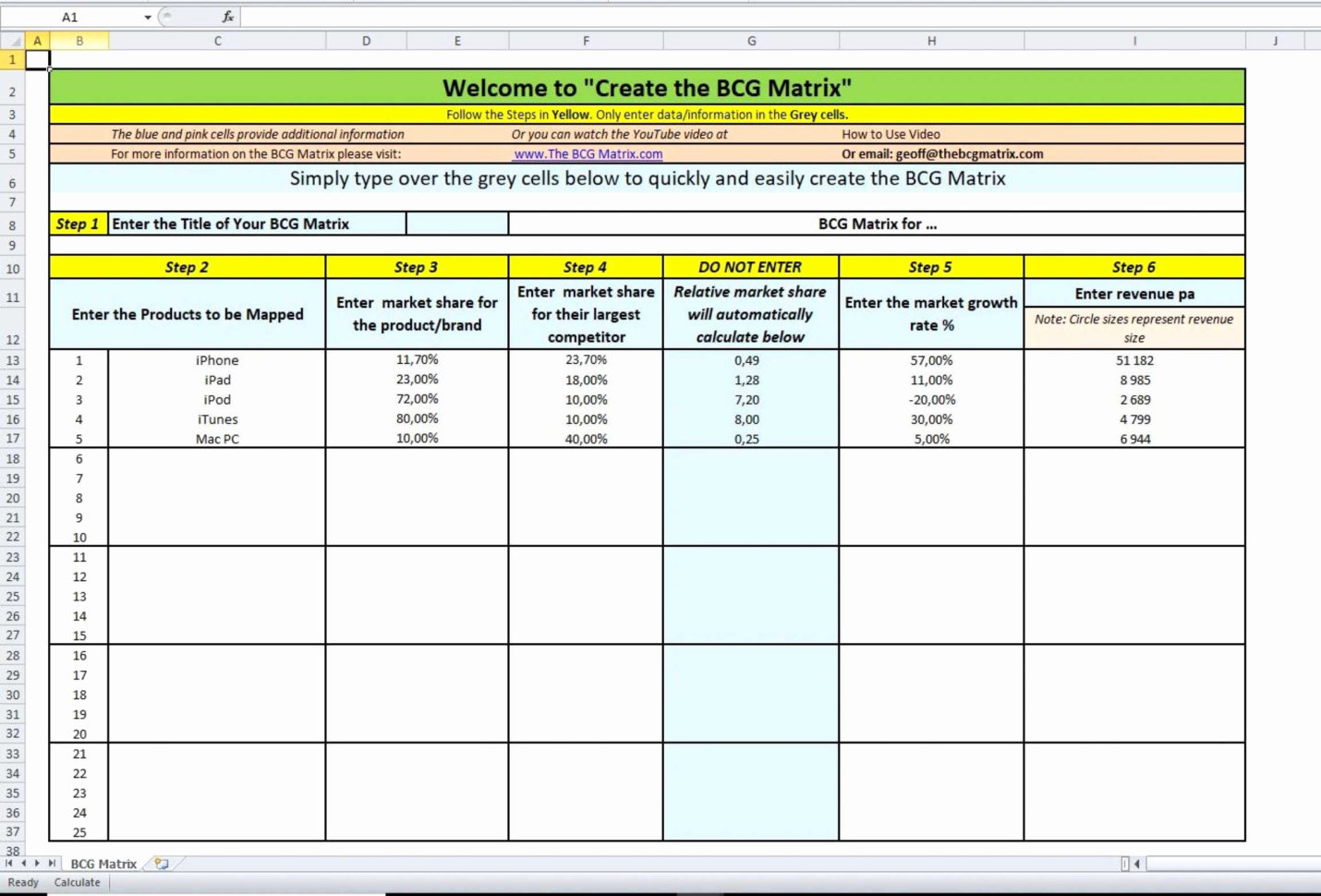

The best way to understand the importance of inventory and the importance of having a dependable and accurate system in place to manage it is to look at the extremes – stock-outs and overages. The Importance of Inventory Management Good inventory management is also important to the long-term financial health of a business. What is used will depend on the type of the business. Also, methods such as Just in Time (JIT), Materials Requirement Planning (MRP), or Reorder Point/Reorder Quantity (ROP/ROQ) are some of the popular approaches that could be applied to become more effective.

#Stock inventory manager software#

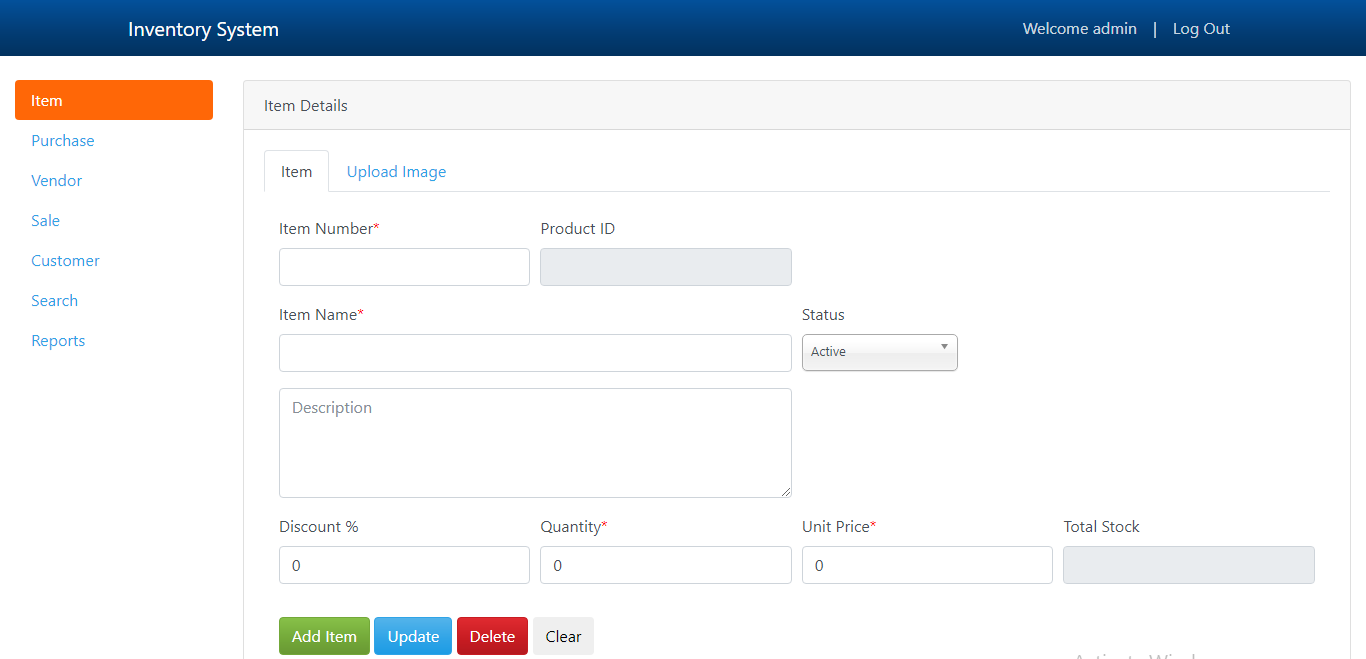

Inventory management is an integral part of overall supply chain management and consists of the planning and ordering process for materials and components needed to produce finished goods, storage of the items, the organization of the warehouse, and organizational processes like inventory receipt and handling procedures, stock lot tracking, documentation of stock movements, order picking for shipment, and much more.īecause modern manufacturing covers a large range of complexity and must keep track of an enormous number of Stock Keeping Units, there is more than one way of managing inventory. To be effective, narrow-focused inventory management software or broader manufacturing ERP software are needed. Inventory management also stretches from raw materials through finished goods, and depending on the industry or mode of production, may include work in process (WIP). Inventory includes materials that need to be processed or assembled and can include consumables such as chemical solutions needed for processing as well as complete sub-assemblies like circuit boards, housings, and other items.

In fact, inventory value can often exceed the value of production equipment and is an important capitalized asset. Inventory is as much an asset like a piece of equipment and must be managed with the same level of care. It is a dynamic and critical part of the production effort itself. Inventory isn’t just a warehouse of “things needed for business”. It starts with the purchase of components and ends with the sale of the product. Inventory management is the process of managing the movement and activity of all physical assets required to produce goods in the manufacturing process.

#Stock inventory manager how to#

0 kommentar(er)

0 kommentar(er)